Olds Vertical Elevators

Olds Elevator

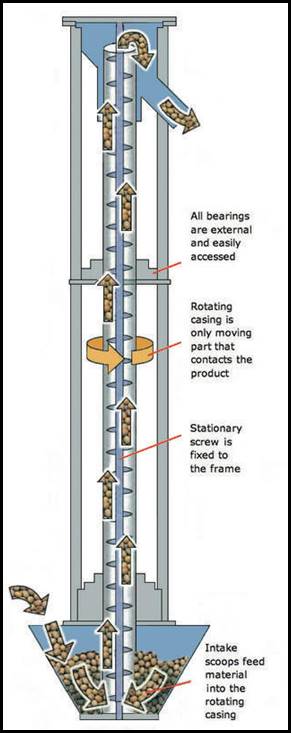

The Olds Elevator is a groundbreaking innovation for vertically elevating an extensive array of bulk materials. With the presence of merely one moving part, the outer rotating casing, We can confidently state that this elevator adeptly gathers and elevates materials to the designated discharge point. The unit functions with a seamless and noiseless operation, and we are proud to highlight its capability to allow an infinite range of delivery rates, adjustable from 0 to 100% of RPM. This feature truly sets it apart as an exceptionally precise metering device.

Within the rotating casing, you’ll find two pick-up scoops positioned at its base. These scoops play a pivotal role in gathering and introducing the product to the stationary screw located inside the casing. They cleverly leverage centrifugal force to maintain the product against the inner wall while additional material is steadily introduced at the base. To guarantee precise movement, adjustable guides are in place to facilitate the centralized rotation of the casing. This casing, in turn, is securely mounted on a bearing in close proximity to the drive system.

The Olds Elevator has the remarkable ability to handle a wide variety of materials. This includes substances such as foundry sand, casting sand, sugar, coal, flocculant, fertilizer, beans, rice, plastic pellets, stockfeed pellets, iron ore lump and fines, nickel concentrate, hydrated lime, quicklime, flour, wheat, cement, SMBS, CMC, as well as viscous slurries like molasses. The Olds Elevator’s capacity to manage such a diverse range of materials underscores its exceptional versatility.

Benefits of the Olds Elevator.

There are numerous advantages associated with the utilization of the pioneering Olds Elevator:

- Streamlined Design: The elevator’s simplicity, featuring only one moving part, translates to minimized spare inventory and maintenance expenses.

- Material Versatility: It excels in elevating various materials without causing any segregation.

- Quiet Performance: A standout feature is its noiseless operational performance.

- Precise Metering: When propelled by a VVVF controller, the elevator exhibits metering capability, enhancing precision.

- Space Efficiency: Its compact footprint allows for effortless retrofitting in existing plants.

- External Bearings: Employing external bearings that avoid contact with the product.

- Dust-Free Operation: Thanks to its unique operational method, the elevator operates in a manner that prevents the generation of dust.

The Olds Elevator’s array of benefits underscores its innovative design and its capacity to meet diverse operational requirements with utmost efficiency.

At Lime Systems, we make sure that the Olds Vertical Elevator is crafted and produced according to the most stringent standards, with a strong emphasis on safety and lasting quality. Our team constructs this elevator using robust materials that can handle non-stop operation, all while following rigorous safety protocols. This includes the incorporation of guard rails, access doors, and emergency stops to ensure maximum security.

What sets the Olds Vertical Elevator apart is its versatility. We offer a range of customization options, allowing you to choose the bucket size, material handling capacity, and drive system configuration that best suits your needs. This adaptability makes the Olds Vertical Elevator an excellent choice for meeting vertical material handling requirements across various industries. Trust in its reliability and cost-effectiveness to provide a dependable solution for your vertical conveying needs.

Clients