Lime Slaking Plant Manufacturer

Lime Slaker Systems

Lime Systems has the right equipment and services for every application, providing convenient and reliable solutions for any project. Our equipment is fully customisable to layout and site conditions.

We can manage the entire process of lime slaking system design, manufacture, and supply. Our expertise covers everything from linking and coupling the delivery tanker to the storage silo, right through to the precise dosing point in the process via the ring main.

We consistently go above and beyond client expectations. Get in touch about your project requirements today.

Lime Systems produces tailored solutions for lime slaking projects, offering support from initial concept through to final delivery and maintenance.

We emphasise safety and durability in our methods, ensuring these aspects are integral from material feed to discharge within the slaking system design. This meticulous approach has earned Lime Systems a solid reputation for producing and delivering hydrated lime in a safe, reliable and highly efficient manner.

Lime Systems clients know us as a trusted supplier of lime slaking equipment to prominent engineering contractors across the globe.

Case Studies

Lime slaking processes

Quicklime, also known as calcium oxide (CaO) or simply lime, is produced by heating limestone or calcium carbonate in big furnaces.

During this heating process, CO2 is released from the stone, resulting in the formation of CaO along with some other small mineral components. This CaO byproduct is what’s commonly recognised as high calcium quicklime.

The process of quicklime slaking involves converting calcium oxide into calcium hydroxide (Ca(OH)2) or slaked lime by adding water to create a lime slurry. It can also be purchased as powdered slaked lime.

Hydrated or slaked lime is commonly used in mining and processing industries. Uses include:

- Water treatment

- Temperature control

- pH control

- Soil stabilisation

In high-use situations it is more economical to install a lime slaking system than to buy the dry powder form, which has a much higher cost per tonne.

Tailored solutions for any application

Our lime slaking systems are designed to produce high quality slaked lime while minimising maintenance requirements and downtime.

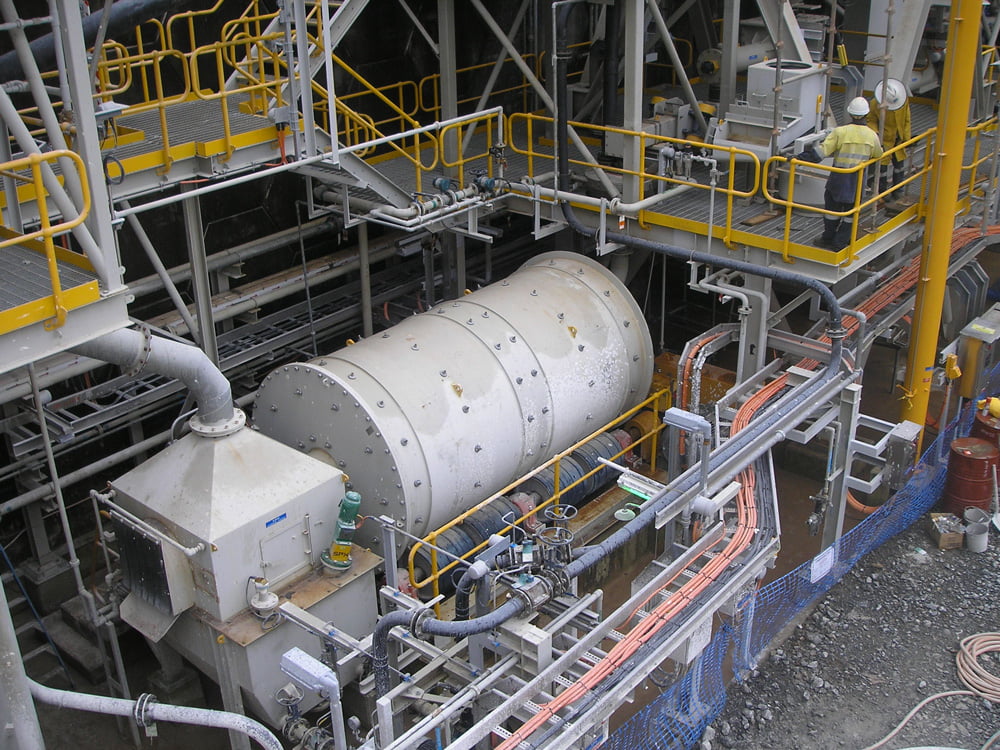

Our equipment and structures are prefabricated as much as possible to make site assembly quicker and easier. We supply and install products for lime storage and slaking, among other projects.

The lime slaking process is completely automated and remarkably efficient. Our lime slaking systems can be installed both indoors and outdoors depending on the site.

Components in typical lime slaking plants include:

- Transfer systems / conveyors

- Storage silos

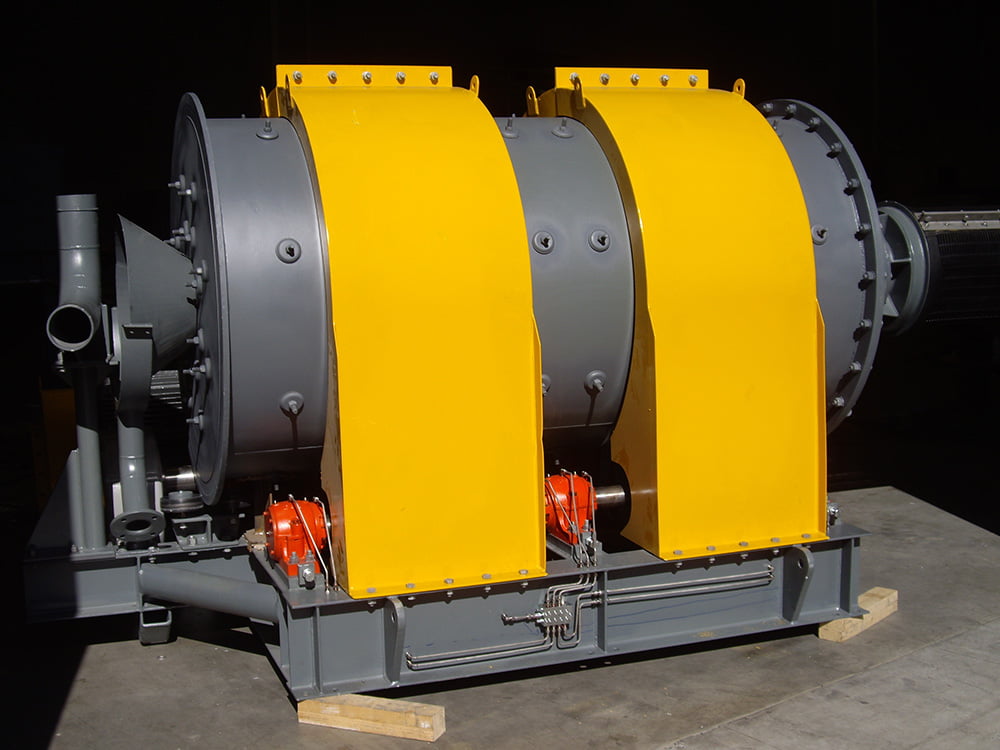

- Roller-mounted ball mills

- Dust controlled bag breaking stations for bulk dry lime

- Plant storage tanks

- Agitated mixing tanks

- Weigh screw for continuous throughput measurement

- Slurry pumps

Quality slaked lime production

Lime quality is always paramount. The two key inputs for the quicklime slaking process are water and quicklime. To make a high-quality slurry, you need the correct ratio of both.

Too much water risks ‘drowning’ the reaction, which can slow the slaking process or stop it taking place effectively. Too little water can cause build-up or blockages in the system and lead to maintenance issues.

Within each lime slaker, you’ll find a chamber equipped with a variable-speed agitator that ensures thorough hydration of the quicklime. The resulting slaked lime moves through a vibrating screen to filter any larger particles before being collected in a slurry tank.

For transporting the lime slurry to its application point, we utilise a range of pumping solutions including:

- Peristaltic pumps

- Centrifugal pumps

- Air-operated diaphragm pumps

This ensures the delivery of quality hydrated lime, ready for use across various industrial applications.

Safe solutions for quicklime slaking

Our customers are often working with hazardous reagents, or in tough site environments with hazards of their own. All Lime Systems pumps, motors, panels and other equipment is appropriately rated to ensure safer operations.

Lime Systems’ proven safety and efficiency when creating turnkey systems, in addition to the fast delivery and high quality of our product, has seen us partner with giants of industry such as BHP Group and Newcrest Mining.

Your project’s success is our priority. Contact us today to find out how we can help.