Screw Feeders

Screw Feeder Manufacturers with Global Experience

Lime Systems specialises in designing and manufacturing screw feeder systems for use across various industries, providing customisable solutions suited to your project’s specific requirements.

Globally trusted as leaders in quality manufacturing of bulk materials handling and storage equipment, Lime Systems’ screw feeders are built for longevity and reliability, with easy maintenance and after-sales support.

Lime Systems also takes into account the unique demands of each application during screw feeder construction, using mild steel, stainless steel, or variations of abrasion or corrosion-resistant materials to make sure every piece performs and lasts

Tailored Screw Feeder Solutions

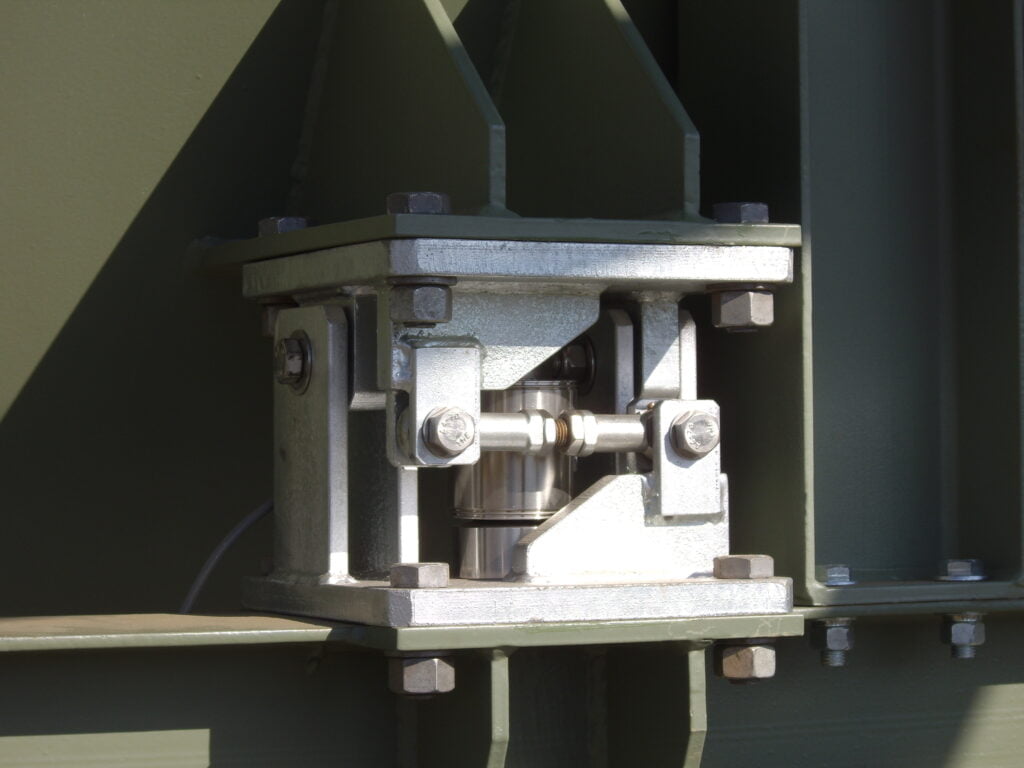

Lime Systems supplies meticulously crafted screw feeder equipment and spares, constructed with heavy-duty materials suitable for mining and other heavy industrial applications. The screws are equipped with specialised shaft sealing, grease-purged labyrinths, and outboard-mounted bearings.

We use only the best quality materials to create our components, so they are hard-wearing, high performing, and reliable even in the harshest environments.

Our dedicated team delivers detailed technical planning and execution support. We work closely with you throughout the process from initial idea to implementation and operations; providing after sales support and technical assistance to ensure everything is running as it should.

See our 5 Stage Gate Process to learn more about how we work.

Whether you are looking for screw feeders as part of a new project or change existing components, Lime Systems can help. Contact our team today to get started.

Efficient Integration of Screw Feeders in Powder Feeding Processes

Screw feeder systems are typically placed at the beginning of a process to provide a reliable solution for feeding powder concentrates into systems.

They can be mounted to a storage bin, hopper or silo (depending on storage capacity requirements) where the product is flood-loaded into the helix of the fully enclosed or trough screw system, which rotates to feed powdered product into the system at the optimal rate.

The discharge rate of a screw feeder can be impacted by:

- Material bulk density

- Conveying efficiency

- Flight filling %

- Screw flight geometry, diameter, and rotation

- Whether it has a mass flow, variable pitch or conical screw design

Designing screw feeders to suit industrial projects requires consideration of what conditions are present in the environment – for example, pressure or vacuum, if the material is lumpy and may not fill the screw’s helix evenly, and potential for abrasion or corrosion over time.

To combat wear and tear and make sure the dosage is consistently volumetrically correct, the construction, size and feed rate of the screw feeder system must suit the characteristics of the material it will convey.

Custom options for screw feeders include:

- Choosing fully enclosed systems or trough systems (dust, spillage, contamination risk)

- Tapering flight shaft or increasing flight pitch

- Manufacturing screws with special materials for food handling, temperature control or corrosive materials (e.g. stainless steels)

- Slower speed screw feeders (for greater durability over time)

- Variable speed drives

- Standard or full ribbon flights

Lime Systems manufactures a range of sizes and configurations to provide precise and dependable screw feeder solutions, particularly for jobs involving bulk materials like lime, ores, minerals, cement, fly ash, and more.

See our recent case studies that demonstrate our capability.

Screw Feeders vs Screw Conveyor

These terms may be used interchangeably at times, though there are technical and functional differences between screw feeders and screw conveyors.

Screw feeders

Deliver a measured dose downstream into your system. They are both space and cost efficient, as well as adjustable in terms of the rate and speed at which bulk materials are dispersed into the system (the feed rate).

They are engineered to add specific amounts of material at a certain point in the process, rather than to move materials over distance. Set up in conjunction with bulk materials storage, screw feeders can be comprised of one or several screws in a live bottom configuration.

Screw conveyors

A screw conveyor moves product from A to B, are typically control loaded, and can be set up in different configurations to convey materials horizontally along lengths, vertically, or at an angle.

If you require a screw conveyor for your project, We can design and manufacture a solution as part of our wide range of purpose-built industrial bulk material handling equipment.

Bulk Material Handling Solutions with Lime Systems

Based in Western Australia and engineered for use in industrial projects around the world, Lime Systems has the expertise and experience needed to ensure smooth planning, delivery and maintenance of essential equipment such as screw feeders, screw conveyors, and storage solutions (hopper, bulk bin, silo) for any material capacity. We’ve provided solutions for some of the biggest mining and mineral companies in the world.

Explore our range of equipment options for any application, or contact us directly to see how we can best help with your next industrial project. Why not reach out to our team today for your bulk materials handling requirements.