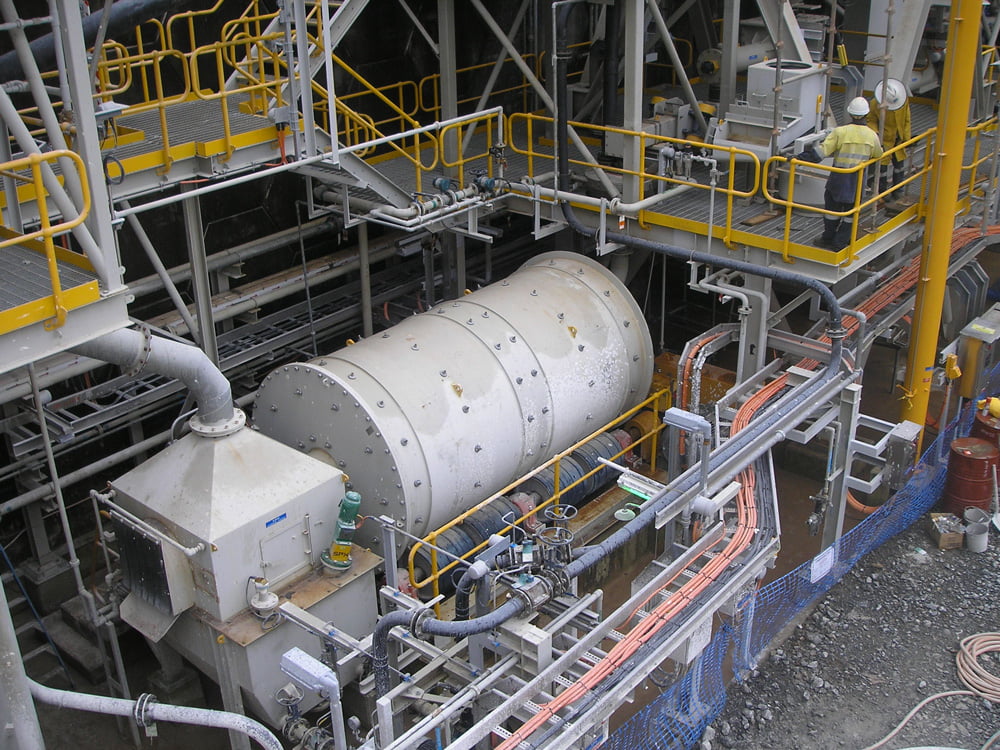

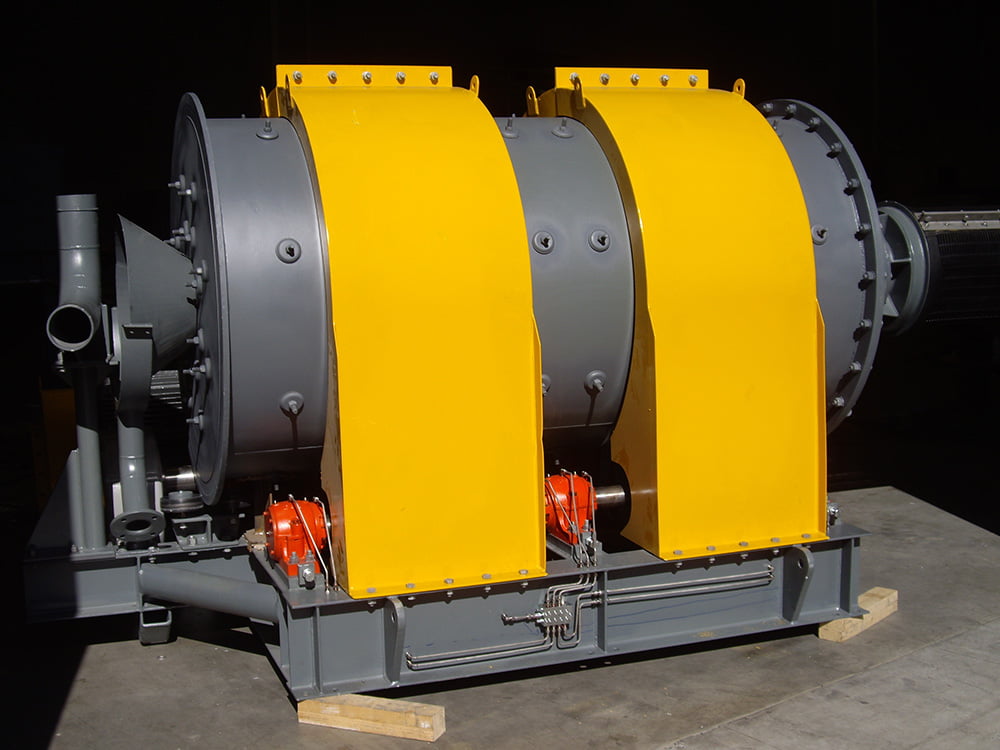

Lime Slaking Plant Manufacturer

Lime Slaker Systems

We manage the entire process of lime slaking system design, manufacture, and supply. Our expertise covers everything from linking and coupling the delivery tanker to the storage silo, right through to the precise dosing point in the process via the ring main.

Our lime slaker expertise spans the globe. Get in touch about your project requirements, and we’ll provide the ideal solution.

We emphasise safety and durability in our provided methods, ensuring these aspects are integral from material feed to discharge within the slaking system design. This meticulous approach has earned Lime Systems a solid reputation for producing and delivering hydrated lime that is not only safe and reliable but also highly efficient. This recognition has led to us being a trusted supplier of lime slaking equipment to prominent engineering contractors on a global scale.

Case Studies

Clients